phone: +385 95 396 1006 • email: info@samac.hr

Production

Harnessing Advanced Manufacturing for Optimal Output

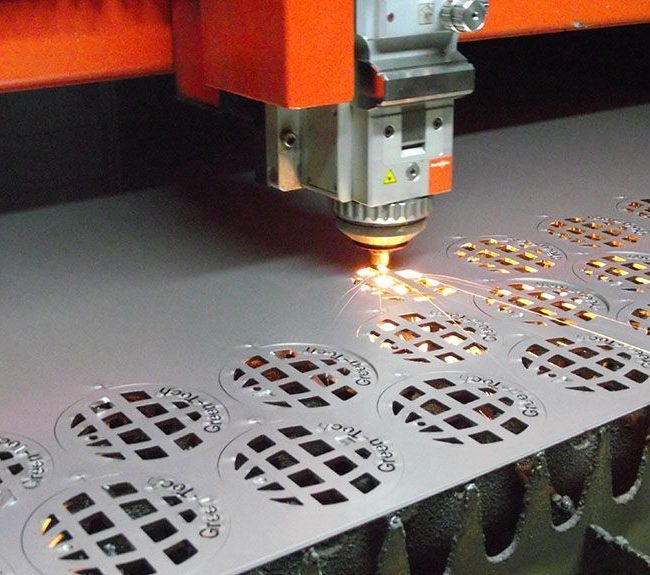

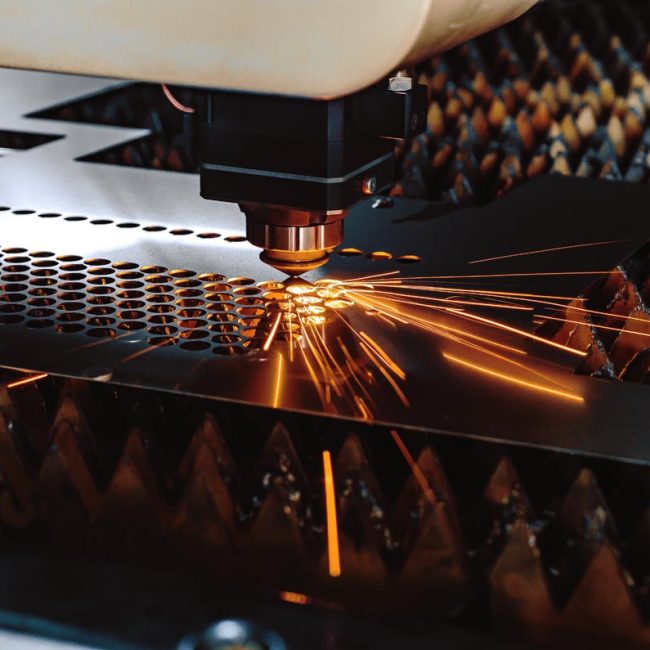

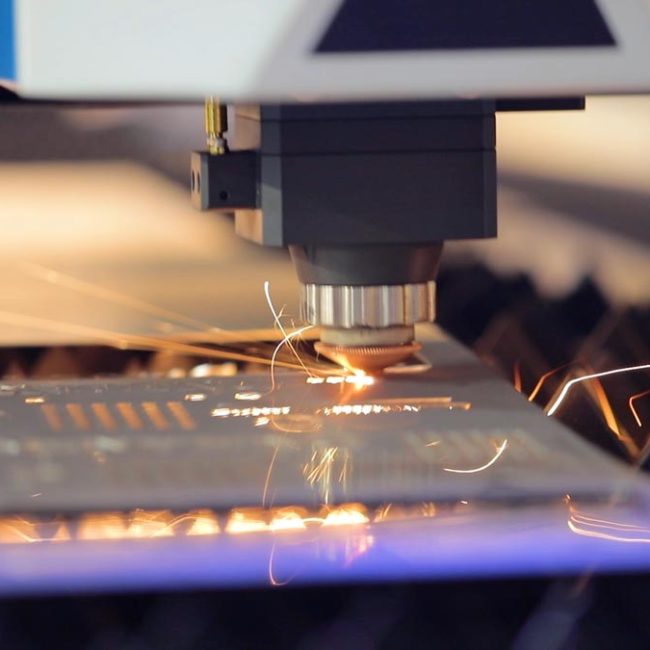

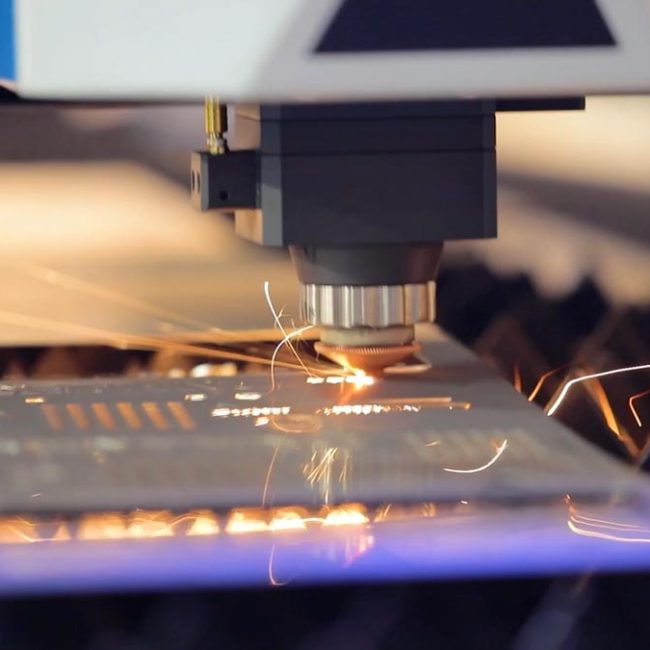

At Samac d.o.o., our production capabilities are centered around mass production, utilizing state-of-the-art technologies to deliver high-volume, high-quality products efficiently. We specialize in processes that ensure precision and scalability, particularly focusing on laser cutting and metal bending, which are crucial for various industrial applications.

Our mass production services are highlighted by our advanced Fiber Laser Cutting machines, capable of handling:

- Stainless steel up to 25mm thickness

- Steel up to 30mm thickness

- Aluminum up to 25mm thickness

- Copper up to 10mm thickness

- Brass up to 12mm thickness

This technology allows us to achieve precise cuts with clean edges and minimal waste, making it ideal for large-scale manufacturing projects. Coupled with our CNC press brake technology, we provide comprehensive metal bending solutions that maintain accuracy across a wide range of material thicknesses and complexities. This combination ensures that we can meet high demands without compromising on the quality and specifications required by our clients.

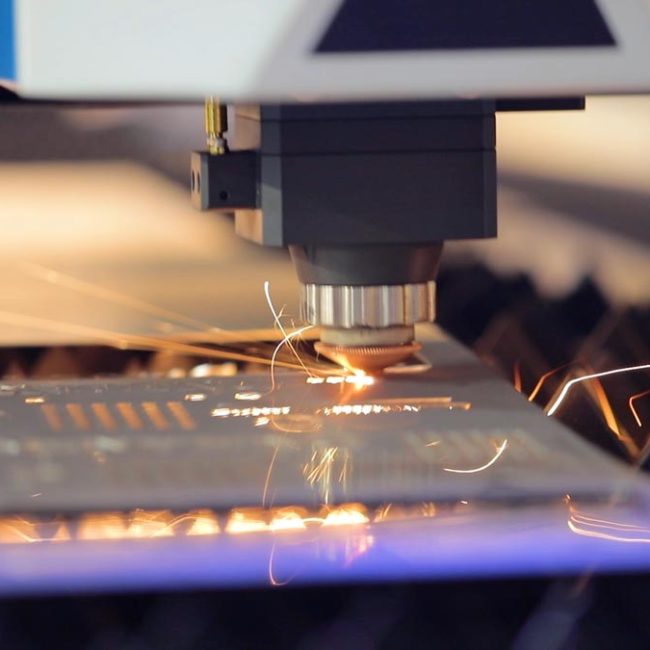

While mass production is at the heart of our operations, we also offer custom production services for clients requiring bespoke solutions. Our custom production leverages the same cutting-edge technologies to offer flexible manufacturing options that can accommodate unique designs, complex configurations, and smaller production runs.

In this segment, we take your concept from design through development to production, ensuring that each custom project is managed with the utmost attention to detail. Whether it’s a prototype or a specialized component, our custom production is about adapting our capabilities to meet your unique needs and specifications.